Polysius

Minimizing lifecycle costs.

Reducing energy consumption.

Stabilizing raw meal process.

Modern grinding solutions that unlock hidden potential in your existing plant

Raw grinding is one of the most energy-intensive and process-critical steps in cement production. It defines material flow, power demand and kiln stability downstream.

Aging equipment, changing raw material properties and suboptimal process settings often reduce efficiency long before problems become visible.

With thyssenkrupp Polysius Raw Grinding solutions, you unlock hidden performance in your existing plant – without building new.

UP TO

20%

OPEX REDUCTION

UP TO

20%

PRODUCTION INCREASE

UP TO

3x

LONGER LIFETIME

Up TO

30%

Higher Availability

UP TO

20%

power savings

Raw Grinding Portfolio

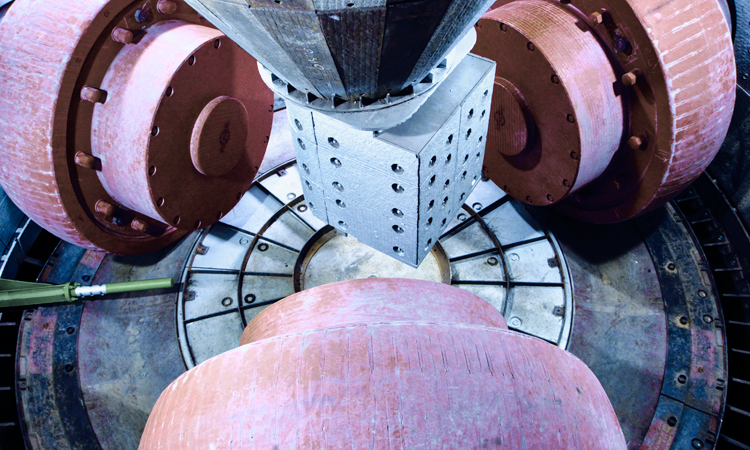

- polycom® High-Pressure Grinding Roll

- Energy-efficient grinding of raw materials

- Can be used as a standalone solution and as a pre-grinding stage

- Extremely high energy efficiency

- Energy efficiency achieved through inter-particle comminution

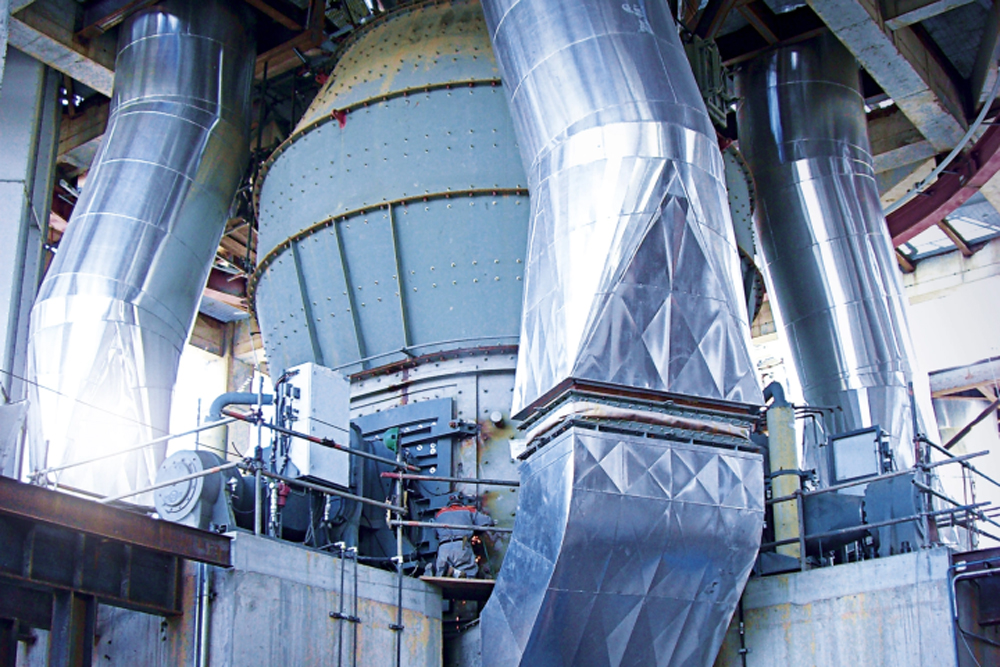

- quadropol® Vertical Roller Mill

- Used for grinding of raw materials and grinding of coal

- Integrated drying included

- High energy efficiency through inter-particle comminution

- Compact design

- High throughputs and drying capacities

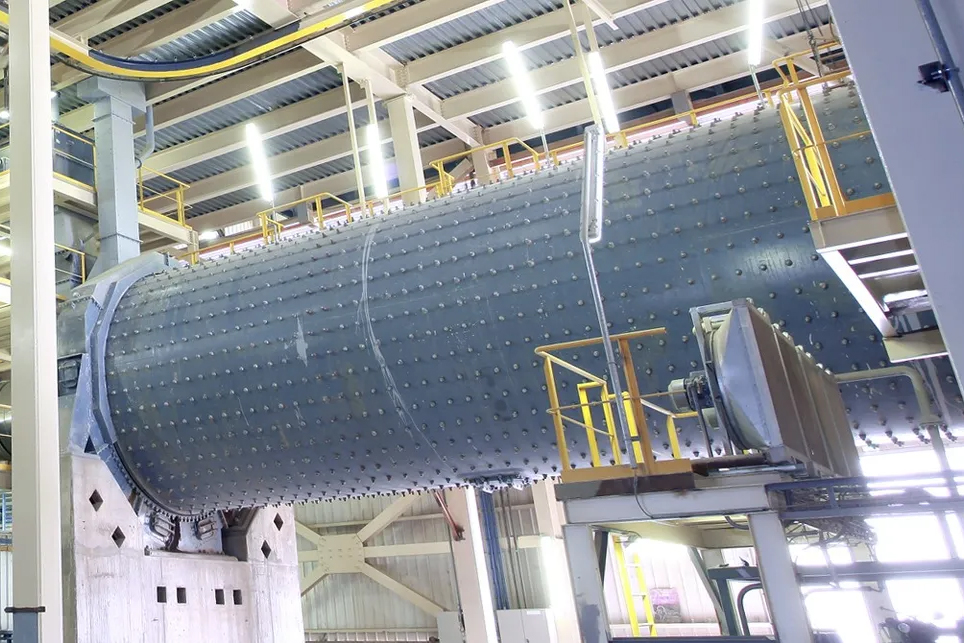

- Ball Mill / Tube Mill

- Used for finish grinding of brittle raw materials

- Used for homogenization of brittle raw materials

- Proven robustness

- Stable operation over decades

- sepol® High-Efficiency Separator

- Used for classification in raw grinding circuits

- Improves grinding efficiency

- Reduces overgrinding and circulating load

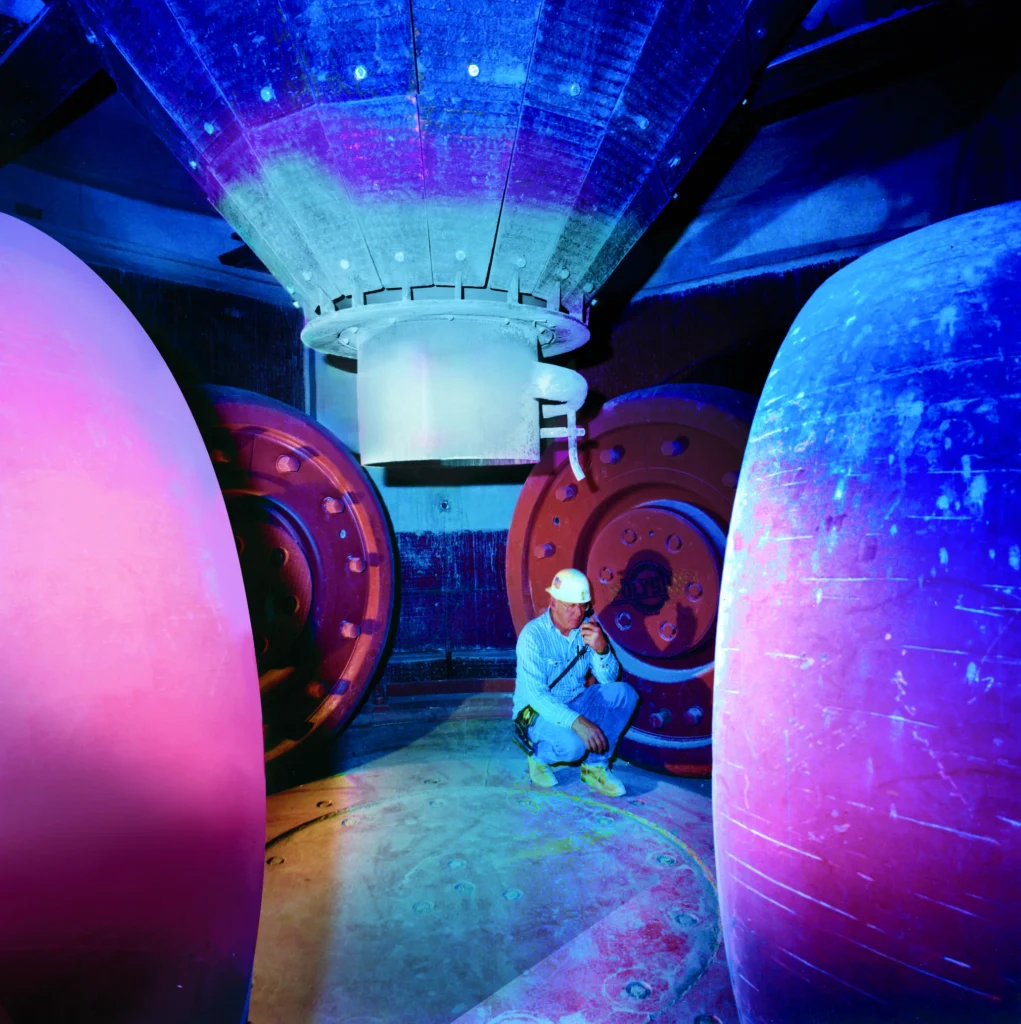

- dorol Vertical Roller Mill

- Grinding of raw materials, coal or petcoke with integrated drying

- Works in combination with ball mills

- Reduces overgrinding and circulating load

- Stable operation

- Low vibration levels and proven, robust design

Your Key Benefits – measurable impact

Up to 20% production increase

Optimized grinding concepts improve the overall efficiency of the grinding process. An improved material intake and reduced false air intake allow higher throughputs while keeping the installed power unchanged. This makes it possible to increase production capacity using existing equipment, without additional energy demand.

Up to 3x longer lifetime

Up to 30% higher availability

Up to 20% power savings

Lower energy consumption is achieved by implementing expert recommendations and mechanical upgrades. By reducing the pressure drop, the grinding system operates more efficiently. This leads to measurable power savings while maintaining stable process performance.

Expert Service

Plants in Africa

including dorol and quadropol®

Our Expert Service was carried out at several cement plants in Africa, including a dorol and a quadropol® vertical roller mill in South Africa. In all cases, the focus was on a comprehensive mechanical and process assessment of the existing grinding systems.

At one site, one of the largest and oldest VRMs of its kind, commissioned in the 1980s, was thoroughly analyzed. The on-site audit identified the root causes of operational instability and defined short-term actions to stabilize operation and reduce power consumption. In addition, long-term improvement measures and critical spare parts were identified to ensure sustained energy efficiency and reliable mill performance.

At another site, a third-party VRM was assessed in close collaboration with the operations and maintenance team. The evaluation covered operating data, machine specifications, and the impact of upgrades implemented during a recent shutdown. Based on these insights, further opportunities were identified to reduce wear, improve output stability, and strengthen long-term process efficiency.

KEY BENEFITS

- Improved operational stability and availability

- Reduced specific energy consumption

- Identification of short- and long-term optimization measures

- Reduced wear and lower lifecycle costs

- Increased transparency regarding mechanical and process conditions

FAQ

What is the potential for energy savings in raw grinding?

By using the polycom® HPGR (High-Pressure Grinding Roll) in combination with a sepol® high-efficiency separator (combi-grinding), you can reduce specific power consumption by up to 20% compared to conventional grinding systems. Optimizing the separator circuit alone can significantly lower the energy demand per ton of material.

How does the quadropol® VRM enhance plant availability through service-friendly design and lifecycle support?

The quadropol® features a modular design with standardized components and improved accessibility, allowing service and maintenance activities to be carried out more efficiently and safely. This helps minimize unplanned downtime and reduces overall maintenance effort. In addition, advanced digitalization tools support condition monitoring and process optimization, enabling stable operation and automatically increasing throughput up to the maximum achievable rate. As a result, plant availability and operational reliability are sustainably improved.

Is it possible to increase the throughput of existing raw grinding plants on short notice?

Yes – targeted system optimizations can unlock additional throughput in existing raw grinding plants within a short time frame.

Specific modifications, such as improving gas flow conditions in dorol and quadropol® mill circuits, reduce pressure losses and increase the available gas volume flow. This directly supports higher mill throughput and improved energy efficiency without major mechanical changes.

In parallel, quadropol® Expert Service audits focus on the complete grinding system – from the nozzle ring and airflow settings to the separator and material circulation. These short, focused inspections allow specialists to identify hidden bottlenecks and implement operational adjustments that can deliver measurable performance improvements within days, depending on the initial plant condition.

Learn more about optimizing your plant: Modernization Portfolio Deep Dive

In a rapidly evolving industrial landscape, staying competitive means getting more out of the assets you already have. During our upcoming 30–45 minute virtual session, we will show how targeted modernizations can unlock hidden performance potential across your plant, boosting throughput, improving efficiency, and reducing OPEX.

Join our experts from thyssenkrupp Polysius as they provide a compact, high‑value overview of modernization levers across the entire process chain: crushing, raw grinding, clinker grinding, pyroprocessing, and laboratory automation.

YOU’LL GAIN INSIGHTS INTO:

- How modernization audits reveal hidden inefficiencies

- What typical performance increases look like

- Which upgrade paths deliver the fastest ROI

WHAT TO EXPECT:

- A practical modernization overview

- Real improvement examples from global plants

- Q&A with our specialists

Stephan Vilbusch

Product Lifecycle Manager – Grinding Applications Cement

Get your Whitepaper & Book your Modernization Portfolio Deep Dive

About us

thyssenkrupp Polysius is one of the leading suppliers of technologies and automation solutions for the decarbonization of the cement and lime industry and, increasingly, for other industries. With more than 160 years of experience, we set standards in the development of innovative technologies and services, as well as a comprehensive and customized service offering that enables sustainable and economical production.

Our services are not only tailored to our own products, but also cover installations from third-party suppliers. Thanks to close cooperation with customers and partners, we are able to meet the specific challenges of our customers and offer them optimal service. This special commitment, coupled with decades of expertise, makes thyssenkrupp Polysius a reliable partner on the road to a sustainable future.

Level Up Your Plant 2026 | Imprint | Data Protection | Cookie-Einstellungen