Polysius

Boost production increase.

Reducing specific energy consumption.

Lower wear rates.

Level up your Cement Grinding Performance – modern grinding solutions that unlock hidden efficiency potential in your existing plant with fast ROI and minimal downtime.

Cement grinding is where efficiency is either unlocked or silently lost. As the final and most energy-intensive step in cement production, cement grinding has a decisive impact on power consumption, product quality, plant availability and overall operating costs. Even small inefficiencies in the grinding circuit are multiplied across the entire production chain and directly affect plant performance.

As grinding systems age, operating conditions change or product requirements increase, performance losses rarely occur suddenly. Instead, grinding efficiency gradually declines and often remains unnoticed in daily operation. During this process, specific energy consumption increases, wear accelerates and process stability is reduced. Over time, grinding capacity decreases, maintenance shutdowns become more frequent and flexibility for different cement types and additives is limited. Without modernization, these effects continue to grow, leading to higher energy demand, reduced reliability and decreasing overall plant stability.

UP TO

30%

OPEX REDUCTION

UP TO

150%

PRODUCTION INCREASE

UP TO

10x

Longer Lifetime

UP TO

15%

Higher availability

UP TO

25%

power savings

Cement Grinding Portfolio

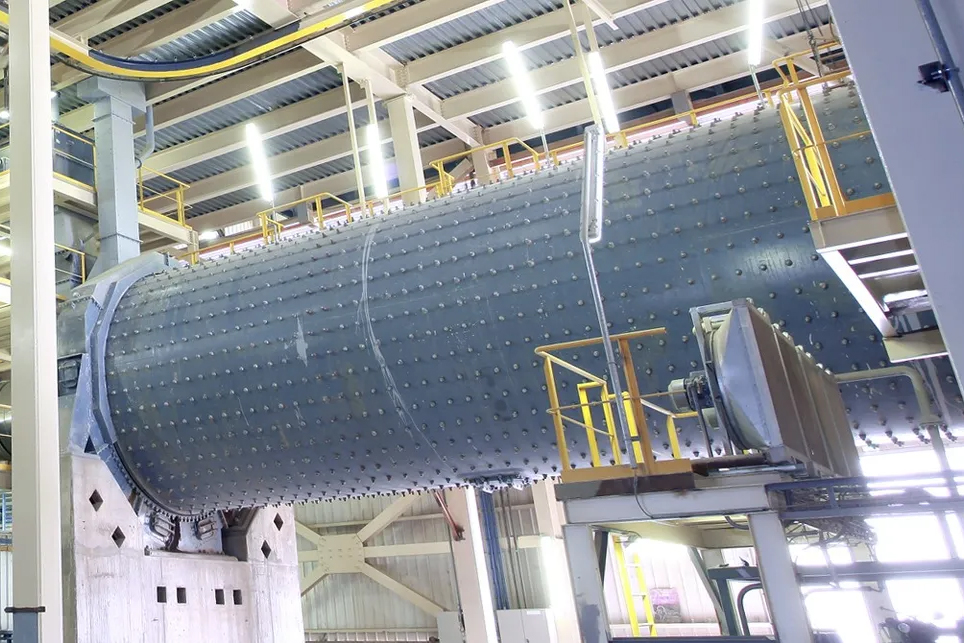

- Ball Mill / Tube Mill

- Used for finish grinding of brittle materials

- Suitable for cement clinker

- Proven robustness and easy operation

- Stable product quantity and quality

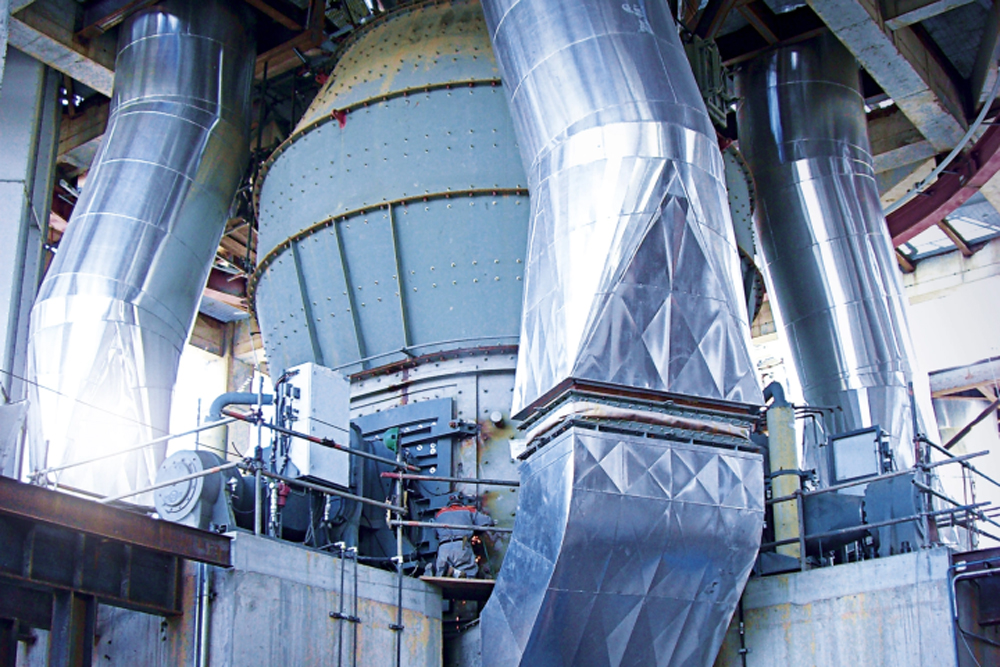

- quadropol® Vertical Roller Mill

- Used for high-capacity clinker grinding

- Suitable for composite cement grinding

- Grinding capacity up to 10,000 t/day

- Up to 50% lower power consumption compared to ball mill circuits

- Integrated grinding and classification

- polycom® High-Pressure Grinding Roll

- Used for pre-grinding or combi grinding of clinker

- Can be combined with a ball mill

- Can be used as a standalone finish grinding stage

- Extremely high energy efficiency through inter-particle comminution

- Up to 50% lower power consumption compared to ball mill circuits

- Cement Cooler

- Designed to maximize energy efficiency and process reliability

- High thermal efficiency

- Reduced power consumption

- Low clinker outlet temperature

- Prepared for future integration with oxyfuel technology

- sepol® High-Efficiency Separator

- Used for classification in clinker grinding circuits

- Reduces overgrinding and circulating load

- Improves grinding efficiency and product fineness

Your Key Benefits – measurable impact

Up to 150% production increase

Up to 10x longer lifetime

Advanced wear protection concepts combined with optimized grinding conditions help reduce mechanical stress on components. This leads to significantly extended service intervals and a much longer component lifetime. By stabilizing operating conditions and minimizing excessive wear, maintenance effort is reduced and equipment remains reliable over a longer operating period.

Up to 15% higher availability

Up to 25% power savings

Power savings are realized through improvements in separation efficiency and a reduction of pressure losses within the grinding circuit. Additional improvements to the grinding method support interparticle comminution, allowing the system to operate more efficiently. Together, these measures significantly reduce energy consumption while maintaining stable grinding performance.

Case Study

sepol® Separator Modernization

Fast Performance Upgrade

Separator efficiency plays a key role in cement grinding and has a direct impact on overall system performance. Efficient separation supports stable operation and improves the effectiveness of the entire grinding circuit. Modernization of sepol® high-efficiency separators provides a fast and cost-effective way to enhance performance without extensive changes to the existing grinding system.

Depending on the project scope, sepol® separator upgrades or replacements can be completed within very short shutdown periods. This makes separator modernization one of the most effective optimization measures in cement grinding, delivering measurable performance improvements with minimal disruption to plant operation.

KEY BENEFITS

- Shutdown periods limited to 5–12 days

- Immediate improvement in classification efficiency

- Reduced overgrinding and lower specific energy consumption

- Reduction of bypass leads to a decrease in recirculation load and ultimately in an increase of production (avg. 8-12%) and / or a reduction of specific energy consumption of 5 to 8%

FAQ

Why is the sepol® separator so effective for plant modernizations?

sepol® features a modular and compact design that allows for easy integration into existing buildings, even where space is limited. It offers high separation efficiency and the ability to cool and dry simultaneously. Modernization projects with the sepol® can often be completed within a short downtime of only 5 to 12 days.

What is the service life of the grinding tools in a polycom® High Pressure Grinding Roll?

When grinding cement, compound cast rollers achieve service lifes of >100.000 hours of operation. This drastically reduces maintenance costs and increase plant availability compared to traditional surface-welding solutions

What are the benefits of the "Combi-Grinding" technology?

Combi-grinding combines the High Pressure Grinding Roll with a ball mill. The polycom® handles the highly energy-efficient pre-grinding, while the ball mill ensures the final product characteristics. Shifting more of the grinding work to the HPGR maximizes the overall system efficiency and lowers the specific energy consumption of the entire plant.

Learn more about optimizing your plant: Modernization Portfolio Deep Dive

In a rapidly evolving industrial landscape, staying competitive means getting more out of the assets you already have. During our upcoming 30–45 minute virtual session, we will show how targeted modernizations can unlock hidden performance potential across your plant, boosting throughput, improving efficiency, and reducing OPEX.

Join our experts from thyssenkrupp Polysius as they provide a compact, high‑value overview of modernization levers across the entire process chain: crushing, raw grinding, clinker grinding, pyroprocessing, and laboratory automation.

YOU’LL GAIN INSIGHTS INTO:

- How modernization audits reveal hidden inefficiencies

- What typical performance increases look like

- Which upgrade paths deliver the fastest ROI

WHAT TO EXPECT:

- A practical modernization overview

- Real improvement examples from global plants

- Q&A with our specialists

Stephan Vilbusch

Product Lifecycle Manager – Grinding Applications Cement

Get your Whitepaper & Book your Modernization Portfolio Deep Dive

About us

thyssenkrupp Polysius is one of the leading suppliers of technologies and automation solutions for the decarbonization of the cement and lime industry and, increasingly, for other industries. With more than 160 years of experience, we set standards in the development of innovative technologies and services, as well as a comprehensive and customized service offering that enables sustainable and economical production.

Our services are not only tailored to our own products, but also cover installations from third-party suppliers. Thanks to close cooperation with customers and partners, we are able to meet the specific challenges of our customers and offer them optimal service. This special commitment, coupled with decades of expertise, makes thyssenkrupp Polysius a reliable partner on the road to a sustainable future.

Level Up Your Plant 2026 | Imprint | Data Protection | Cookie-Einstellungen