Polysius

Boost Throughput.

Reduce OPEX.

Extend Lifetime.

Level up your Crushing Performance - Modern crushing solutions that unlock hidden potential in your existing plant with fast ROI and minimal downtime.

Crushing is the starting point for plant performance in cement production. As the first process step, cement crushing directly affects material flow, throughput, energy consumption and wear behaviour across the entire plant. When crushing systems are not modernized or raw material conditions change, crushing efficiency and capacity gradually decline, often without being noticed in daily operation.

Over time, reduced crushing performance leads to higher energy demand, more frequent maintenance shutdowns and decreasing process stability. These inefficiencies increase operating costs and limit overall plant efficiency and reliability. Optimizing and modernizing cement crushing systems is therefore essential to maintain stable production, improve energy efficiency and protect long-term plant performance.

UP TO

30%

OPEX REDUCTION

UP TO

20%

POWER SAVINGS

UP TO

40%

LONGER LIFETIME

UP TO

60%

HIGHER AVAILABILITY

UP TO

25%

CAPACITY INCREASE

Crushing Portfolio

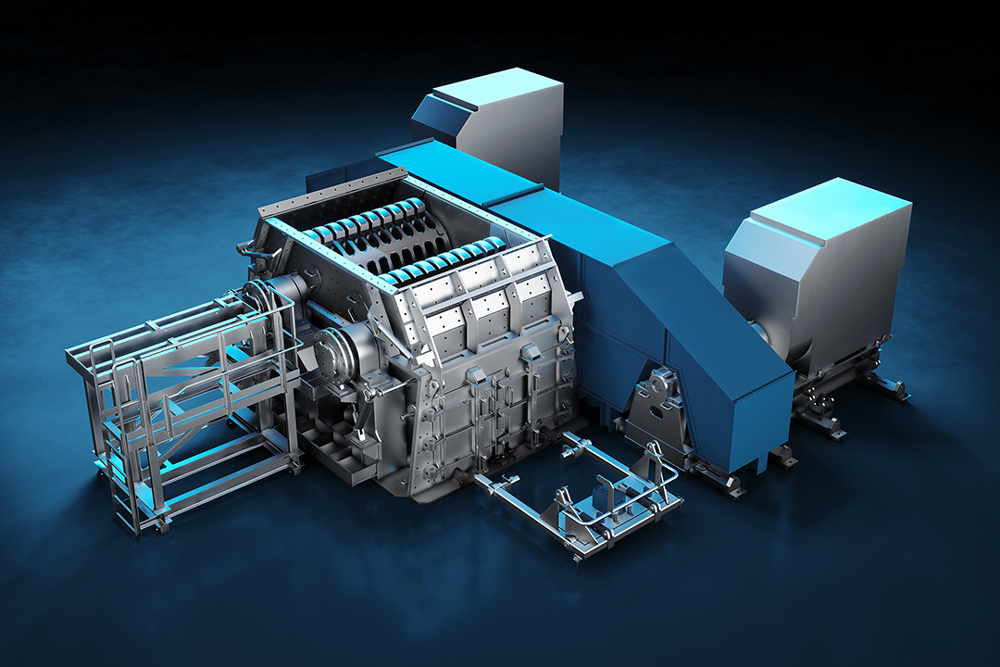

- titan® Double Shaft Hammer Crusher

- Efficient crushing (highest reduction rate of all available crusher types) of wet or sticky materials up to 20 %

- Suitable for VRM and ball mill feed

- Simultaneous feeding of multiple materials

- Robust construction and high throughput

- Produces 0/80 mm for VRM or 0/35 mm for horizontal ball mills

- mammut® Single Shaft Hammer Crusher

- Primary crushing of limestone

- <8 % moisture mainly

- Used as primary crusher at cement plant with horizontal ball mills as raw meal grinding plant

- High reduction via rotor impact

- Robust and simple maintenance

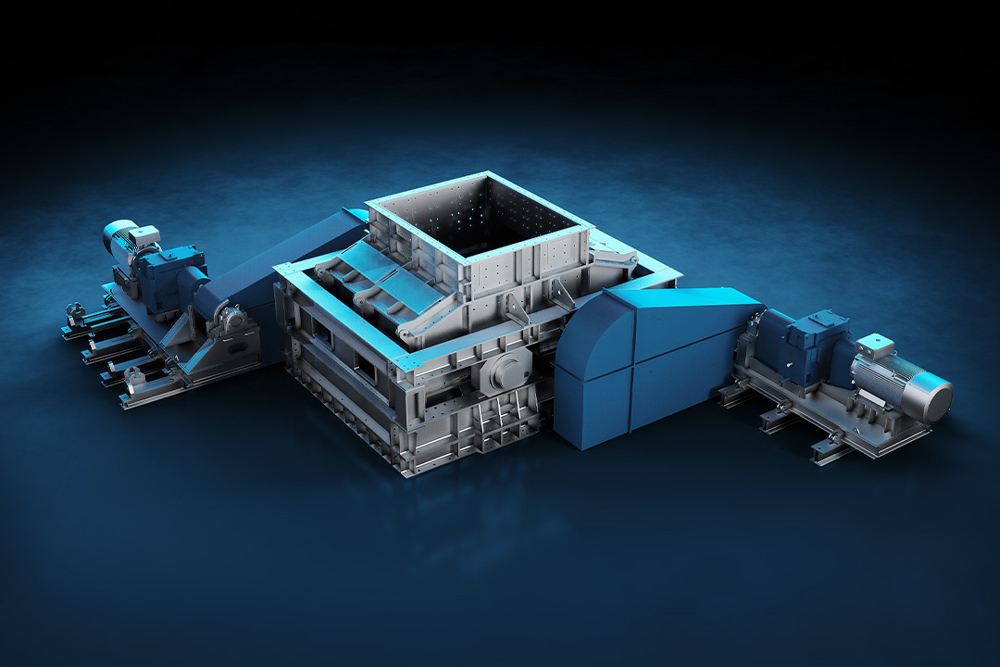

- Double Roll Crusher

- Combines pressure, impact, shear, and tensile forces for crushing

- Suitable for sticky and abrasive materials

- Limited hardness (max. 175 MPa)

- Efficient processing and robust construction

- Very good applicability to crush moist and sticky materials like clay

- Ideal for plants with high recycling within raw material feed

- Overload protection for uncrushable

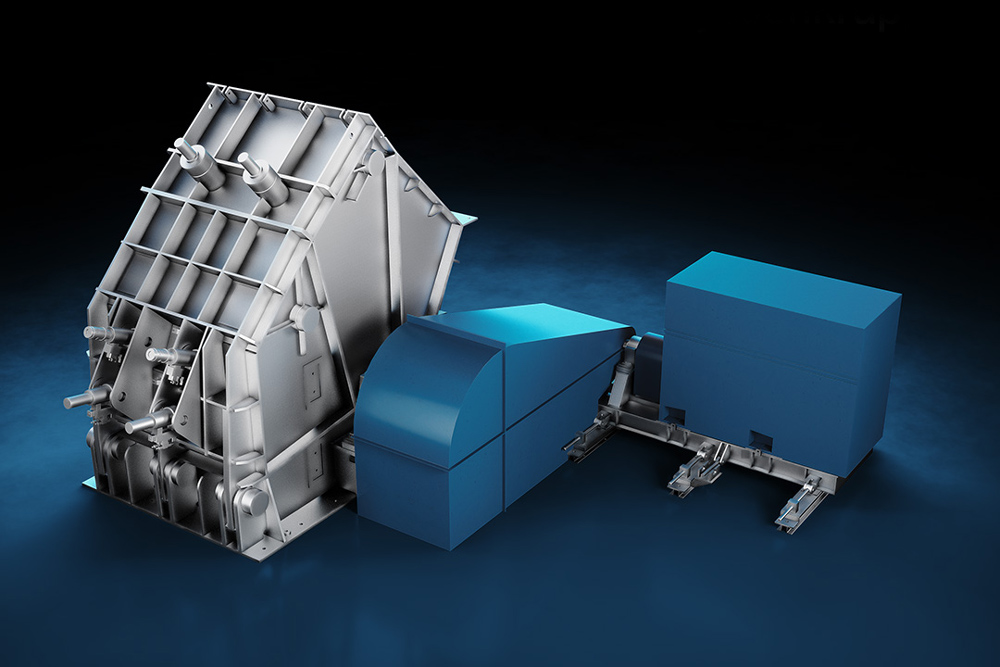

- Impact Crusher

- Hydraulic adjustable impact plates for precise particle size

- Moderate feed moisture up to 8 %

- High capacities and high reduction rates

- Hydraulic gap adjustment during operation

- High crushing efficiency, durability and reliability

- Tramp metal protection & easy maintenance

- Wobbler / Roller Screen

- Screening and cleaning as well as coarse sizing of dirty feed materials in primary crushing

- Pre-screening before the crusher

- Removal of fine limestone

- Protects downstream crushers

- Reduces crusher load and lowers wear

- Increases overall plant throughput

- Individually configured depending on application

- Apron Feeder

- Feeding heavy, coarse, abrasive raw material with high impact loads under bunkers and in front of crushers

- Handles uneven feed

- High load capacity and high mechanical strength

- Low maintenance effort and efficient material feeding

- Variable feeding, suitable for large lump sizes

- Tailored for each application

Your Key Benefits – measurable impact

Up to 20% Power savings

Upgrading the hydraulic drive unit to electromechanical drive system improves resilience, decreases power consumption by frequency converter and reduces the spare part costs.

Up to 40% longer lifetime

Up to 60% higher availability

Up to 25% capacity increase

Optimized rotors, modular upgrades and smart integration significantly increase throughput, availability and efficiency.

Case Study

Apron Feeder Modernizations

Honduras & Germany

thyssenkrupp Polysius has long-standing expertise in apron feeder modernization and the conversion of existing installations to the robust polysius® RKF design.

The projects in Honduras and Germany demonstrate how targeted retrofit concepts can significantly improve reliability, efficiency and service life while keeping shutdown times short and investment costs under control.

In Honduras, an existing apron feeder was converted to an RKF 2,000 × 10,750-D7 configuration.

In central Germany, apron feeders at a cement plant were fully modernized under extreme operating conditions, including winter temperatures down to –20 °C. Further projects included conversions to RKF 2,000 × 11,900-D6 and RKF 1,500 × 9,500-D4 designs.

The modernization strategy focused on replacing wear-intensive components while retaining major structural elements wherever possible. Newly designed single-pan apron plates with integrated sealing lips prevent material leakage, protect downstream equipment and significantly reduce wear. Plate thicknesses between 10 and 30 mm ensure high resistance against impact and abrasion.

KEY BENEFITS

- Shutdown periods limited to only 2–4 weeks through modular retrofit concepts

- Up to 10% reduction in power consumption and up to 20% maintenance cost savings

- Robust RKF design with lower wear rates and significantly reduced OPEX

FAQ

Why is the rotor design so critical for my operations?

The rotor is the heart of your crusher and the main driver of your operational costs (OPEX). An outdated or incorrectly selected rotor can cause vibrations and structural damage. Our solid designs for Double Roll Crusher for example features a modular design with exchangeable crushing segments. These can be replaced easily without dismantling the entire housing, simplifying maintenance and increasing the equipment’s lifetime by up to 40%.

What are the specific benefits of modernizing my crushing plant?

Modernization is about „leveling up“ your performance. During decades of operation, the raw material changes and the very first machine selection might not be suitable any more. By adapting the wear part configuration, crusher capacity or the final product size, the availability of the crusher itself can be increased up to 60 %. Moreover, the down streamend performance cost of the Raw Mill are significantly influenced. Most of our modernization projects reach a positive Total Cost of Ownership (TCO) in less than five years. Depending on the scope, many modernization measures can be executed during planned shutdowns. Typical implementation times range from a few days for separator upgrades to several weeks for larger grinding circuit modifications.

How does machine communication improve the crushing process?

The frequency controlled apron feeder and the crusher drive are communicating so that an advanced crusher feeding prevent the crusher from overfilling. Moreover, we equip our machines with intelligent sensors for condition monitoring (tracking vibrations and bearing temperatures). Combined with automated lubrication and load-dependent control systems, these tools increase plant availability by up to 30%.

Learn more about optimizing your plant: Modernization Portfolio Deep Dive

In a rapidly evolving industrial landscape, staying competitive means getting more out of the assets you already have. During our upcoming 30–45 minute virtual session, we will show how targeted modernizations can unlock hidden performance potential across your plant, boosting throughput, improving efficiency, and reducing OPEX.

Join our experts from thyssenkrupp Polysius as they provide a compact, high‑value overview of modernization levers across the entire process chain: crushing, raw grinding, clinker grinding, pyroprocessing, and laboratory automation.

YOU’LL GAIN INSIGHTS INTO:

- How modernization audits reveal hidden inefficiencies

- What typical performance increases look like

- Which upgrade paths deliver the fastest ROI

WHAT TO EXPECT:

- A practical modernization overview

- Real improvement examples from global plants

- Q&A with our specialists

Tim Hücking

Head of crushing technology

Service – Modernizations

Get your Whitepaper & Book your Modernization Portfolio Deep Dive

About us

thyssenkrupp Polysius is one of the leading suppliers of technologies and automation solutions for the decarbonization of the cement and lime industry and, increasingly, for other industries. With more than 160 years of experience, we set standards in the development of innovative technologies and services, as well as a comprehensive and customized service offering that enables sustainable and economical production.

Our services are not only tailored to our own products, but also cover installations from third-party suppliers. Thanks to close cooperation with customers and partners, we are able to meet the specific challenges of our customers and offer them optimal service. This special commitment, coupled with decades of expertise, makes thyssenkrupp Polysius a reliable partner on the road to a sustainable future.

Level Up Your Plant 2026 | Imprint | Data Protection | Cookie-Einstellungen